How Is Fiberglass Insulation Made?

Fiberglass insulation, a staple in both residential and commercial buildings for its thermal and acoustic insulating properties, has a fascinating production process. This post will explore how this ubiquitous material is made, highlighting the technology and processes involved.

The Basics of Fiberglass Insulation

Fiberglass is a type of fiber-reinforced plastic where the reinforcement fiber is specifically glass fiber. Its key properties include non-conductivity, fire resistance, and sound absorption, making it an ideal material for insulation.

Raw Materials Used

The journey of making fiberglass insulation begins with raw materials, predominantly sand and recycled glass. These materials are chosen for their availability and suitability in creating durable glass fibers. Additives like boron are often included to enhance the material's fire-resistant properties.

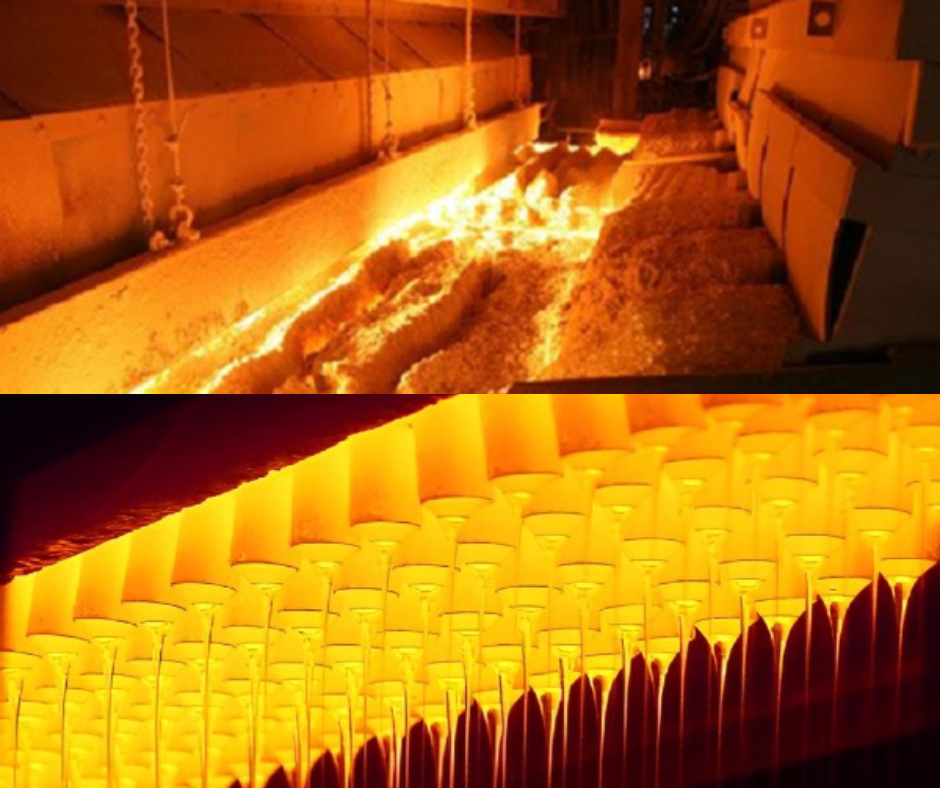

Melting and Fiberizing Process

In the manufacturing plant, these materials are melted at extremely high temperatures, often exceeding 1,000 degrees Celsius. The molten glass is then extruded through fine nozzles, a process known as fiberizing, creating thin strands of glass fibers.

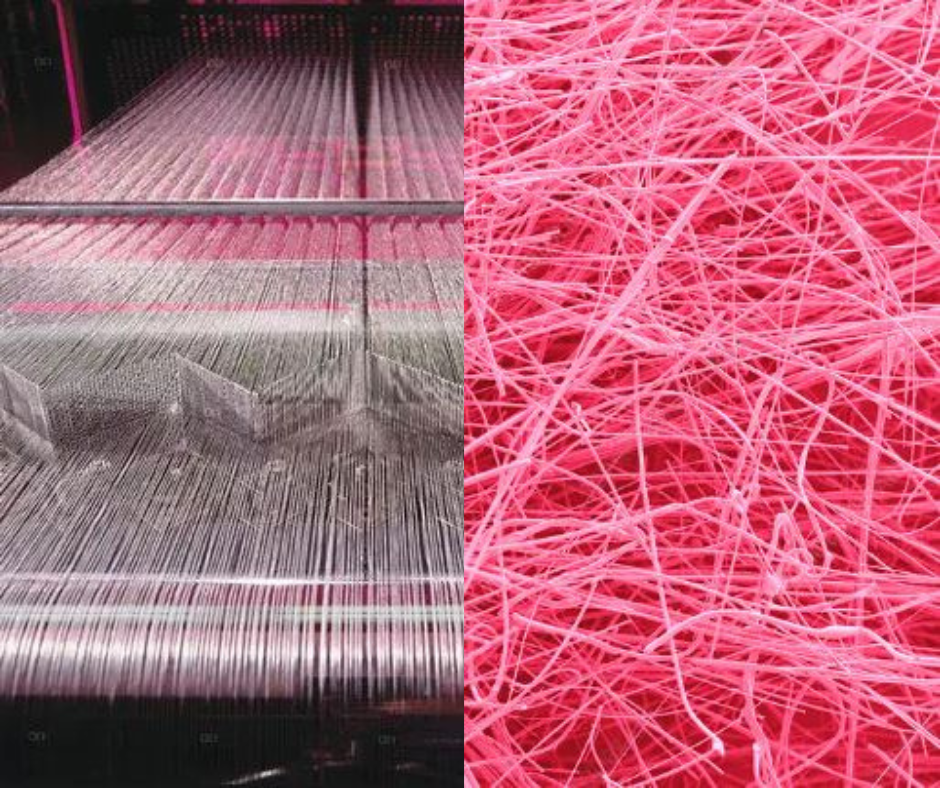

Forming the Insulation Material

Once formed, these fibers are then assembled into insulation materials, such as rolls or batts. A binding agent is often applied to ensure the fibers stick together and maintain their shape. The thickness and density are adjusted depending on the intended use.

Forming the Insulation Material

Once formed, these fibers are then assembled into insulation materials, such as rolls or batts. A binding agent is often applied to ensure the fibers stick together and maintain their shape. The thickness and density are adjusted depending on the intended use.

Cutting and Packaging

After the insulation takes shape, it’s cut into various sizes to fit different applications, from attic spaces to wall cavities. The final product is then compressed and packaged, ready for distribution and installation.

Quality Control and Testing

Throughout this process, rigorous quality control measures are in place. The insulation is tested for its thermal and acoustical properties, ensuring it meets industry standards and safety regulations.

Environmental Considerations

Fiberglass insulation production is not just about efficiency but also sustainability. The use of recycled glass reduces waste, and manufacturers are continually seeking ways to reduce energy consumption during the production process.

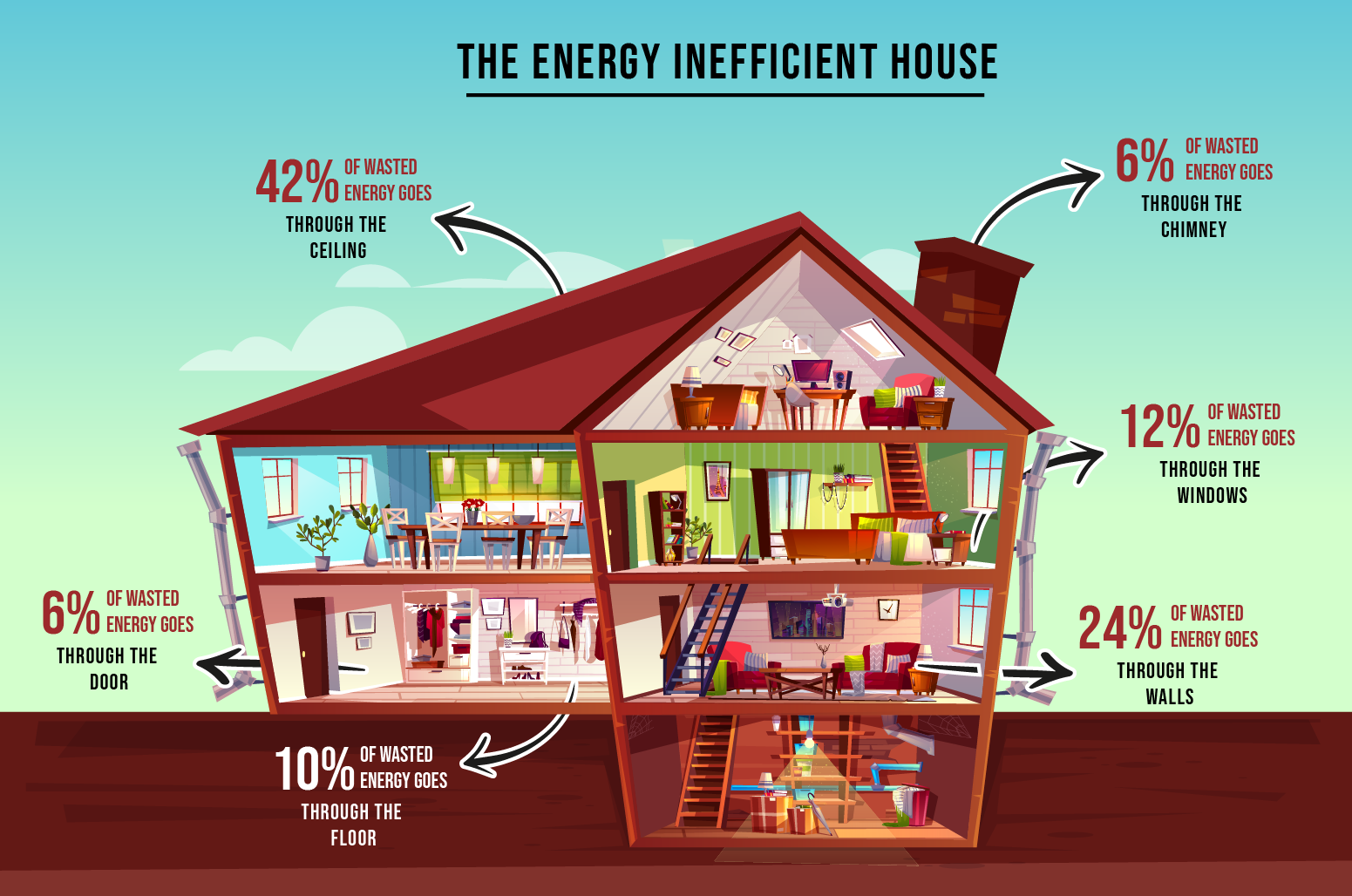

Conclusion: The making of fiberglass insulation is a blend of science and engineering, producing a material crucial for energy efficiency and comfort in buildings. Its manufacturing process, from the selection of raw materials to the final product, demonstrates a commitment to both quality and environmental sustainability.

Are you considering the right insulation for your home or project? Remember that the quality and type of insulation you choose can significantly impact energy efficiency and comfort. For expert advice on insulation options, including fiberglass, contact us at [Your Company]. Our team is ready to guide you in selecting the best insulation for your needs.

Foam Pros Saskatoon

Foam Pros Saskatoon is a specialist spray foam insulation company that services the surrounds of Saskatoon. We specialize in expanding foam insulation for ceilings and walls in both commercial and residential spaces.

Privacy Policy Contact Us More Resources

All calls from our site are sent to a qualified contractor.

Built by RenovateROI - A Home Contractor Marketing Company